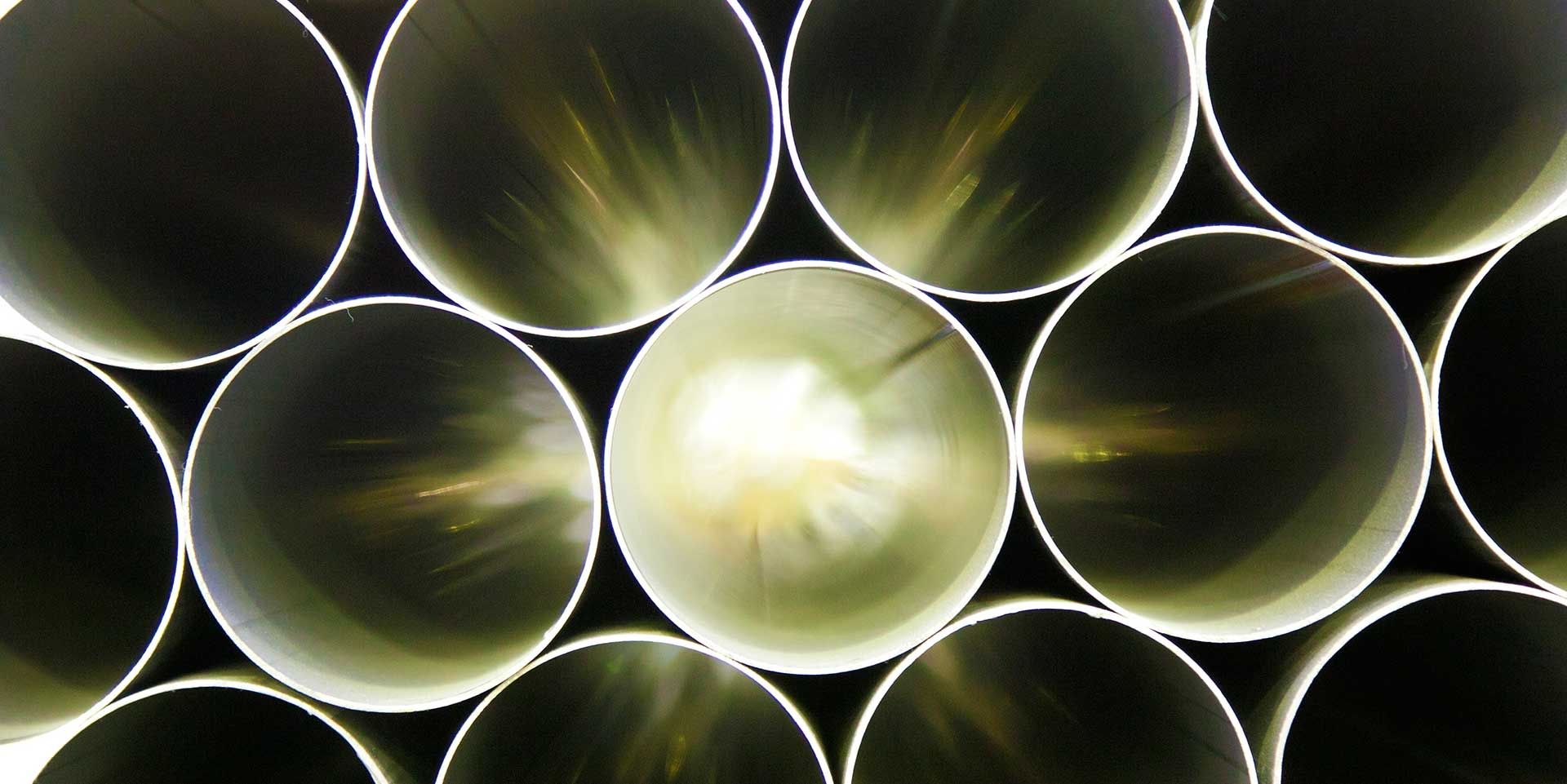

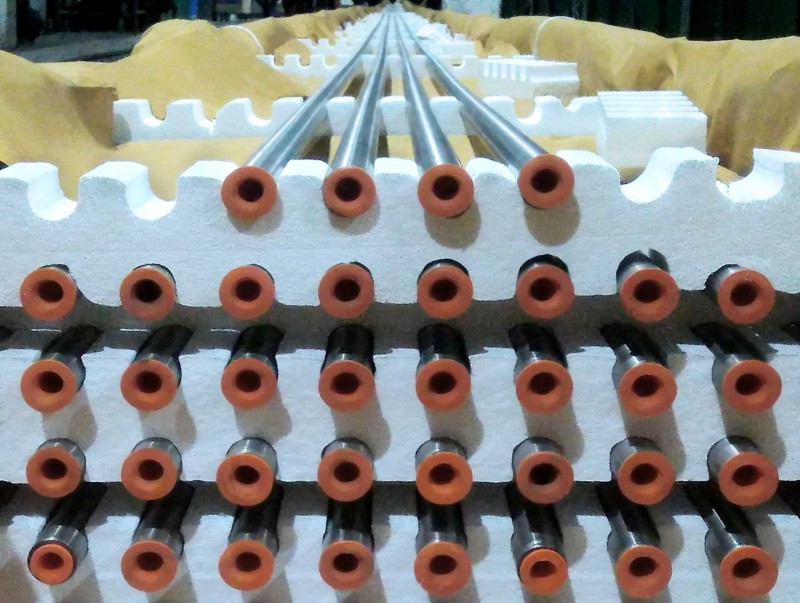

TMK to start pipe shipments to Hungary

TMK is starting its first pipe shipments to Hungary. A customer in Hungary will purchase 9.2 tonnes of small diameter stainless steel pipes manufactured by TMK’s subsidiary TMK-INOX. TMK will supply seamless cold-deformed small diameter pipe subjected to special non-oxidizing he...