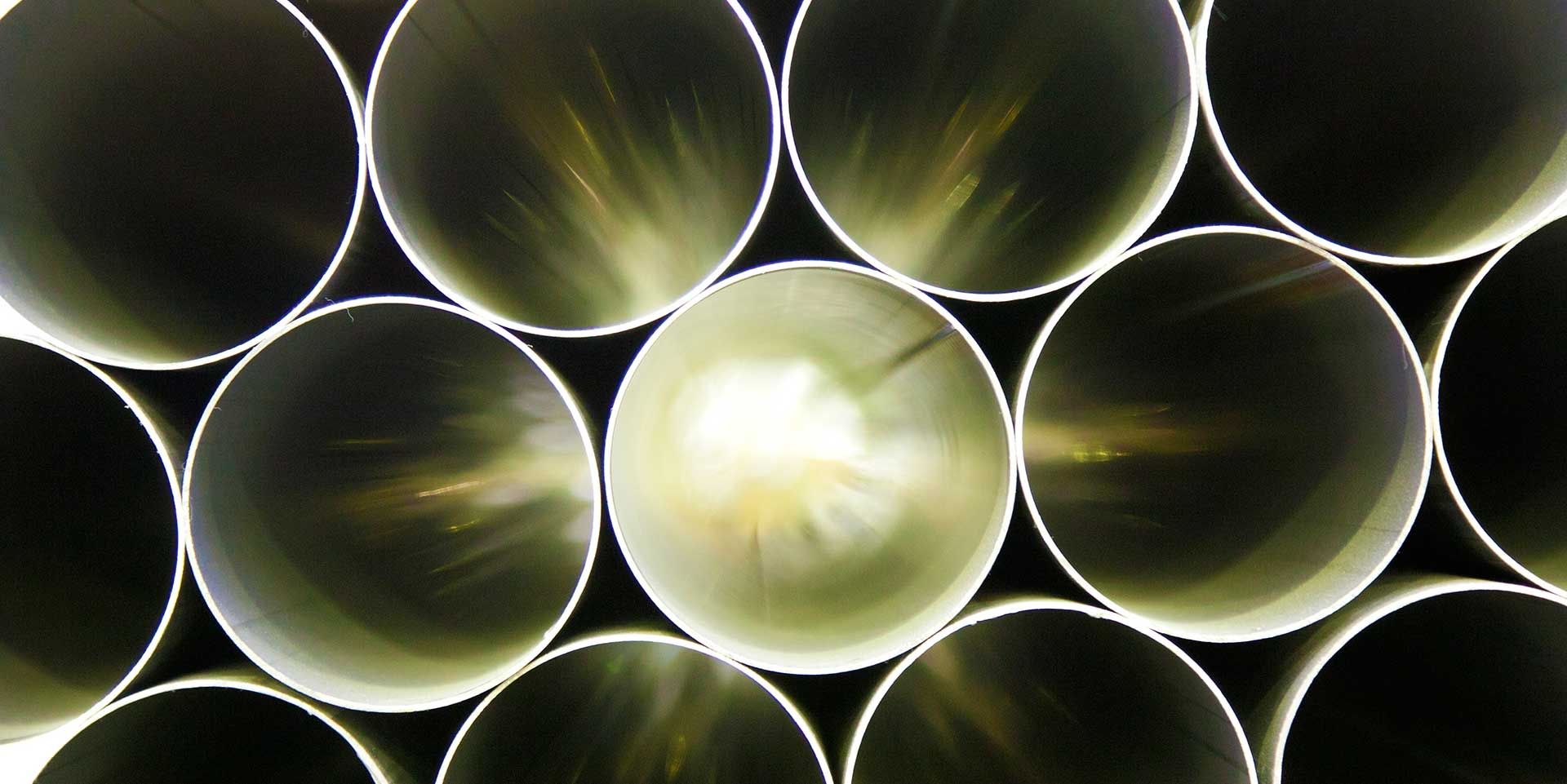

TMK-INOX, a subsidiary of TMK, has commissioned a shop manufacturing stainless steel and alloy-based welded precision pipes.

Two welding lines produced by Italy’s OLIMPIA 80 Srl, a leading manufacturer of pipe welding equipment, were installed at the plant. At the next stage of the welded stainless steel pipes production development, a top-of-the-line high-performance large stainless steel coil slitter is to be commissioned.

The new welded stainless steel pipe shop produces high-quality pipes conforming to world-class samples and standards (DIN 17457-11850, ASTM A249, A269, A270, and NFA 49147-49249), which are in great demand with car manufacturers, food, energy, and construction companies.

According to the project plans, after reaching their full production capacity the lines will annually produce 10,000 tonnes of high-tech welded stainless steel and alloy pipes.

“The new shop commissioning marks the second stage of the precision stainless steel pipes manufacturing as part of our unique TMK-INOX project. When starting our nanotechnology-based production of seamless stainless steel pipes two years ago, we laid the groundwork for our expansion into the emergent market niche of special-purpose pipes. With the production of welded stainless steel pipes now in place, we are ready to further strengthen our market position by offering our customers a wide range of innovative products in this segment,” said Alexander Shiryaev, TMK CEO.

TMK Commissions New Production Lines at TMK-INOX (210.77 KB,pdf)

TMK to start pipe shipments to Hungary

11.11.2020TMK to supply Rosatom with unique pipes for its pilot fast neutron reactor

05.12.2019TMK-INOX celebrated the 10th anniversary

08.10.2019TMK-INOX recognized with the certificate of commendation of the ROSATOM state corporation

07.08.2018TMK-INOX launches a new complex for lubricant removal from long-length tubes

16.05.2017TMK-INOX expands the range of electric welded stainless tubes