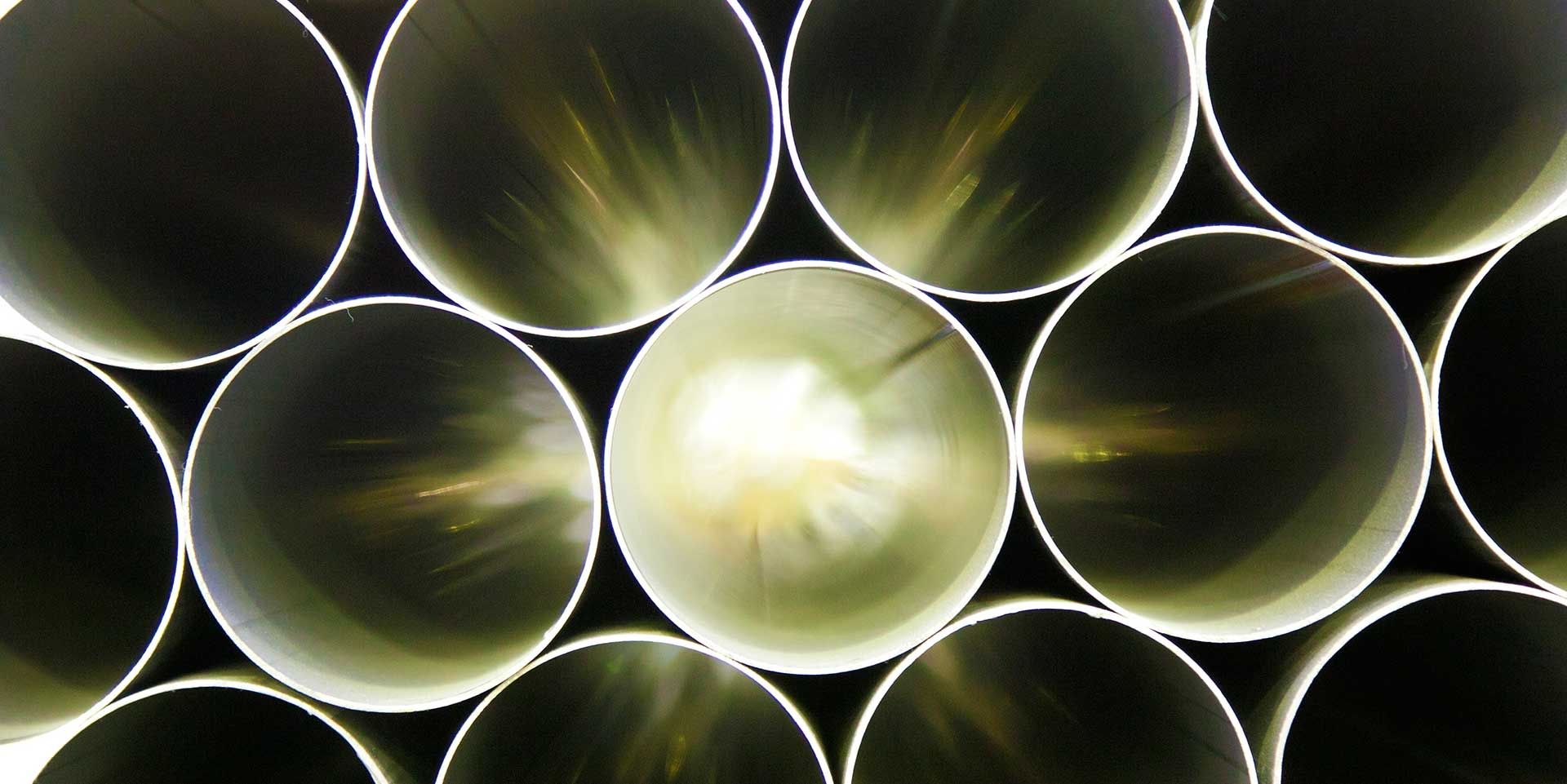

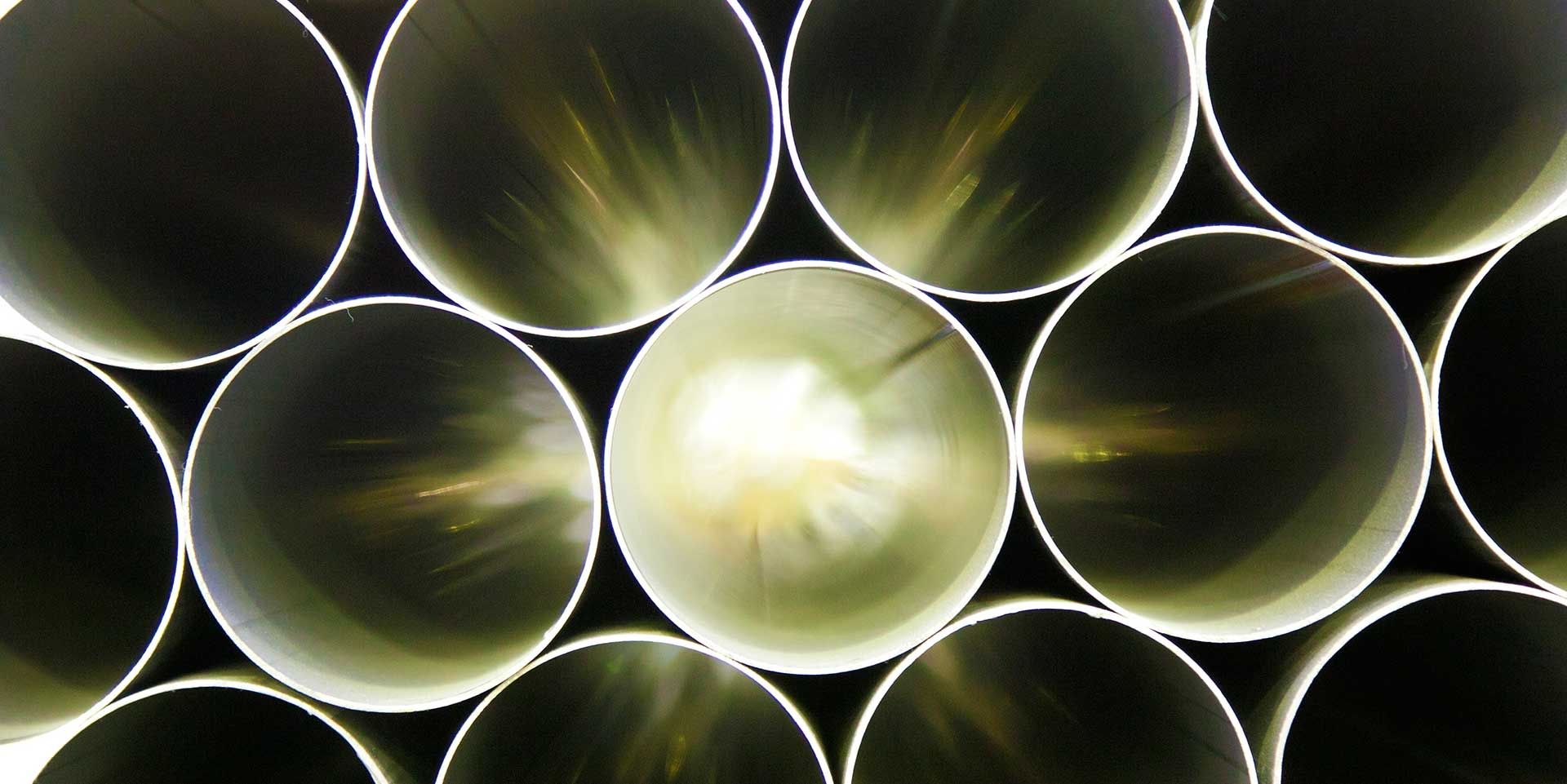

An installation for long-length tubes quality control by ultrasonic method UMK-25, including rotary inspection system and transport mechanization of tube feeding was put into operation at TMK-INOX (a joint project of RUSNANO and TMK) at the site in Kamensk-Uralsky.

The installation allows controlling the quality of seamless tubes with an outer diameter of 10-25 mm and a length of up to 31 meters. The new equipment brings out defects in the outer and inner surfaces both longitudinally and transversally, and monitors tube geometrics and ovality. The use of this installation will increase the productivity of non-destructive testing at the enterprise up to 10 times.

The installation for tube control was commissioned as part of the project to equip the TMK-INOX site in Kamensk-Uralsky with equipment designed for the production of stainless tubes up to 31 meters long. Earlier, a Cold Pilger Mill and pickling baths were put into operation.

“Having commissioned new equipment for non-destructive testing, we completed a long-term project to equip the long-length tube production, implemented jointly with specialists from the Sinarsky Pipe Plant and RosNITI, - said Alexander Borshchevsky, CEO of TMK-INOX. “As a result, we got the opportunity to manufacture products that meet additional increased requirements for surface quality and geometrics of tubes, which will positively affect its competitiveness in the market.”

TMK to start pipe shipments to Hungary

11.11.2020TMK to supply Rosatom with unique pipes for its pilot fast neutron reactor

05.12.2019TMK-INOX celebrated the 10th anniversary

08.10.2019TMK-INOX recognized with the certificate of commendation of the ROSATOM state corporation

07.08.2018TMK-INOX launches a new complex for lubricant removal from long-length tubes

16.05.2017TMK-INOX expands the range of electric welded stainless tubes