A through-type gas furnace SYTCO with ultra-pure hydrogen protective atmosphere was put into operation at TMK-INOX (a joint project of ROSNANO and TMK) at the site in Kamensk-Uralsky, as part of the strategic program for reconstruction of the stainless cold-worked tubes production.

The SYTCO furnace is an automated unit equipped with a visualization system for technological parameters. The inlet and outlet sides of the furnace are fully mechanized.

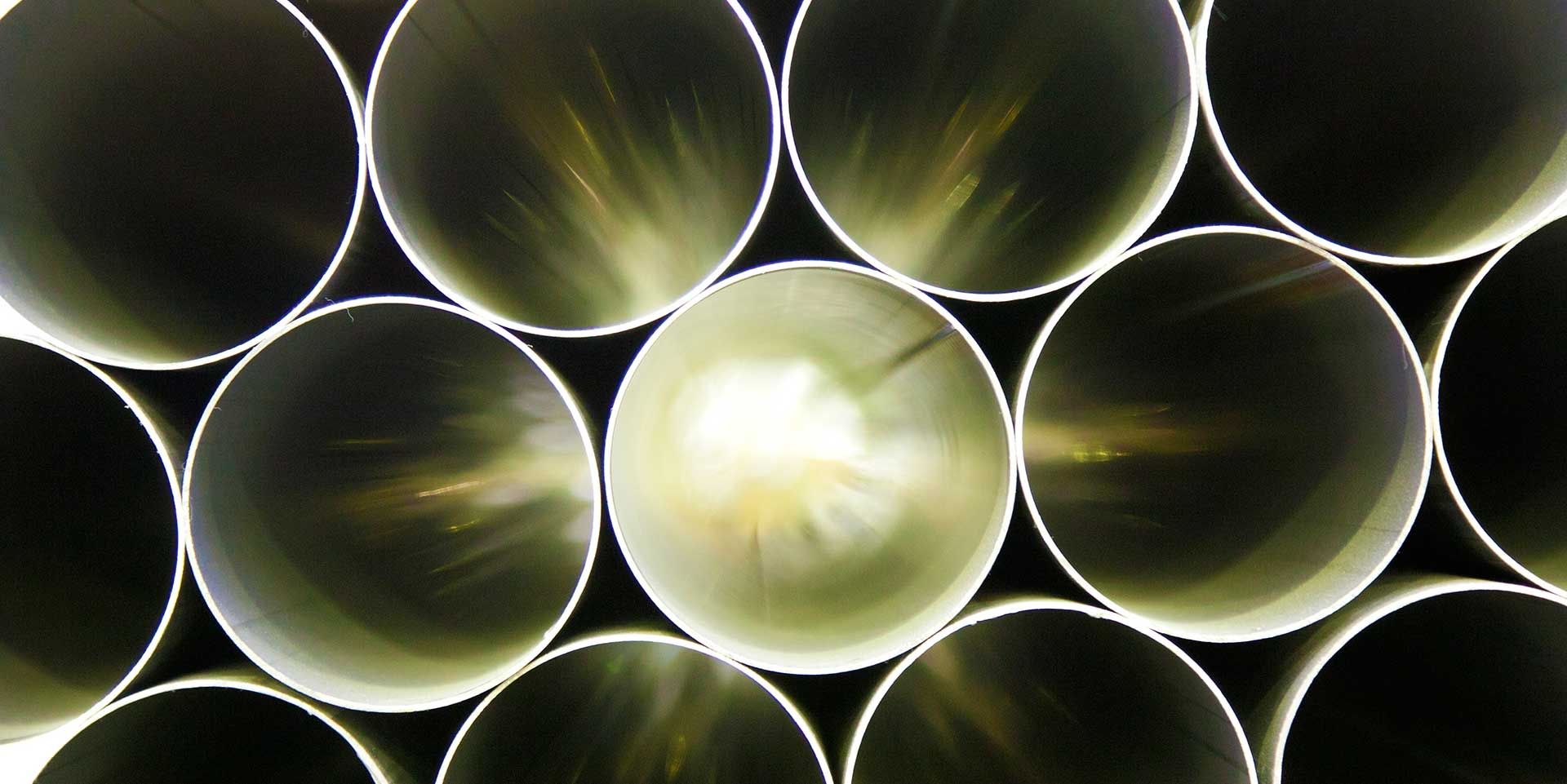

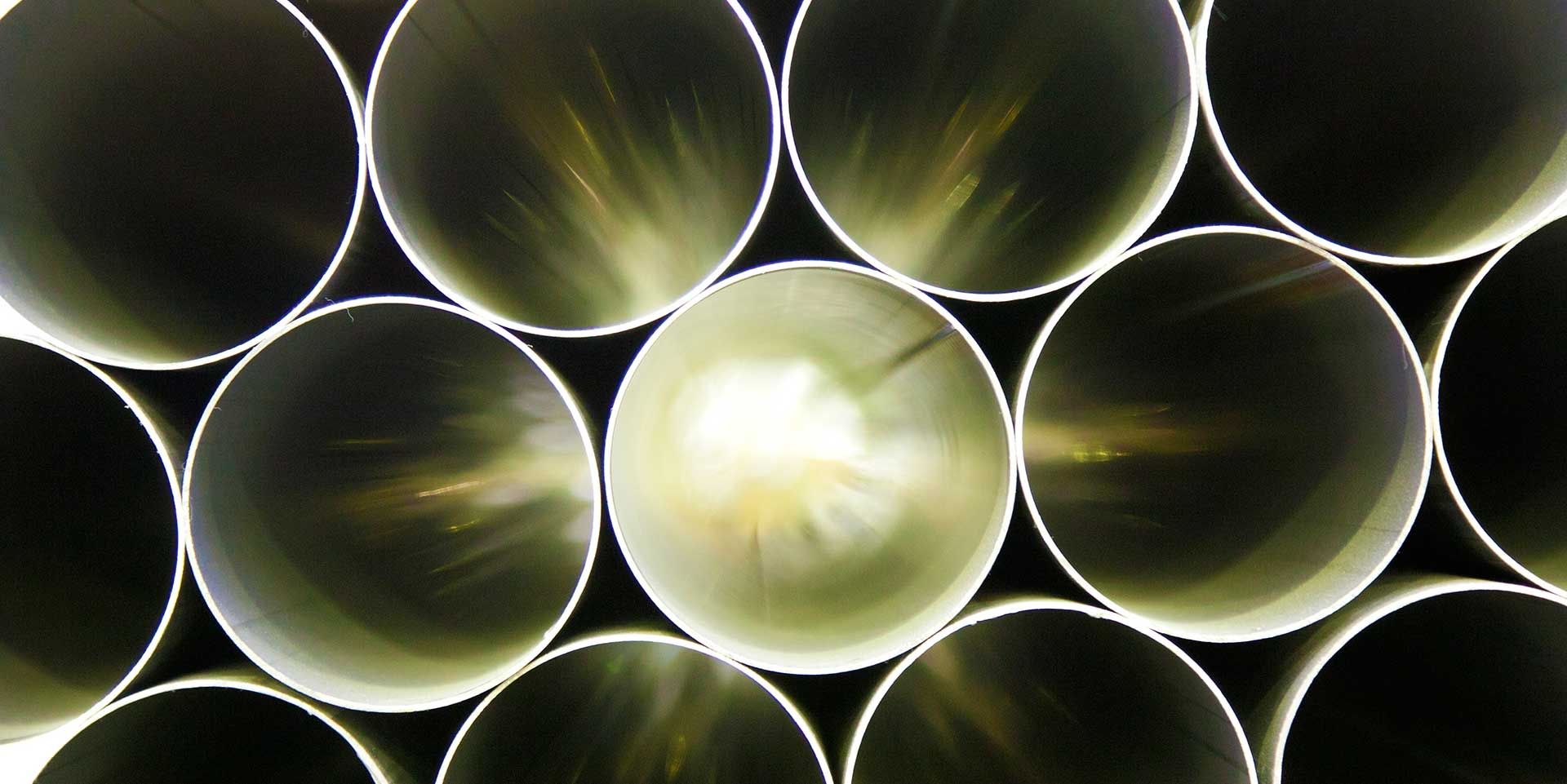

The new equipment has a capacity of up to 500 kg/h; the length of the furnace is 100.3 m, which makes possible to heat-treat tubes with a diameter of 8 to 60 mm, with a wall thickness of 0.5 to 5 mm and a length of up to 30 m.

The advantage of the unique furnace, which has no analogues in Russia, is a new technology for heat treatment of tubes in ultra-pure hydrogen protective atmosphere, which excludes the effect of external sources of oxidation on the processes occurring on the tubes surface. As a result, tubes come out from the new furnace without scale, with light inner and outer surface.

When installing the equipment, the issues of workplace management where explored with due diligence: comfortable conditions that meet all the safety requirements were provided for the furnace operator, the levels of vibration and noise were significantly reduced, and emergency safety system was installed.

“Putting of the gas furnace into operation signifies the completion of the main stage of the enterprise’s investment program and the development of tubes non-oxidizing (bright) annealing,” noted TMK INOX CEO Leonid Marchenko. “The implementation of this project provides the manufacturing of the products with improved consumer properties for nuclear and defense industry, helps to reduce ecological environmental impact, and also significantly improves staff working environment.”

TMK to start pipe shipments to Hungary

11.11.2020TMK to supply Rosatom with unique pipes for its pilot fast neutron reactor

05.12.2019TMK-INOX celebrated the 10th anniversary

08.10.2019TMK-INOX recognized with the certificate of commendation of the ROSATOM state corporation

07.08.2018TMK-INOX launches a new complex for lubricant removal from long-length tubes

16.05.2017TMK-INOX expands the range of electric welded stainless tubes